adaptable to walkway construction.

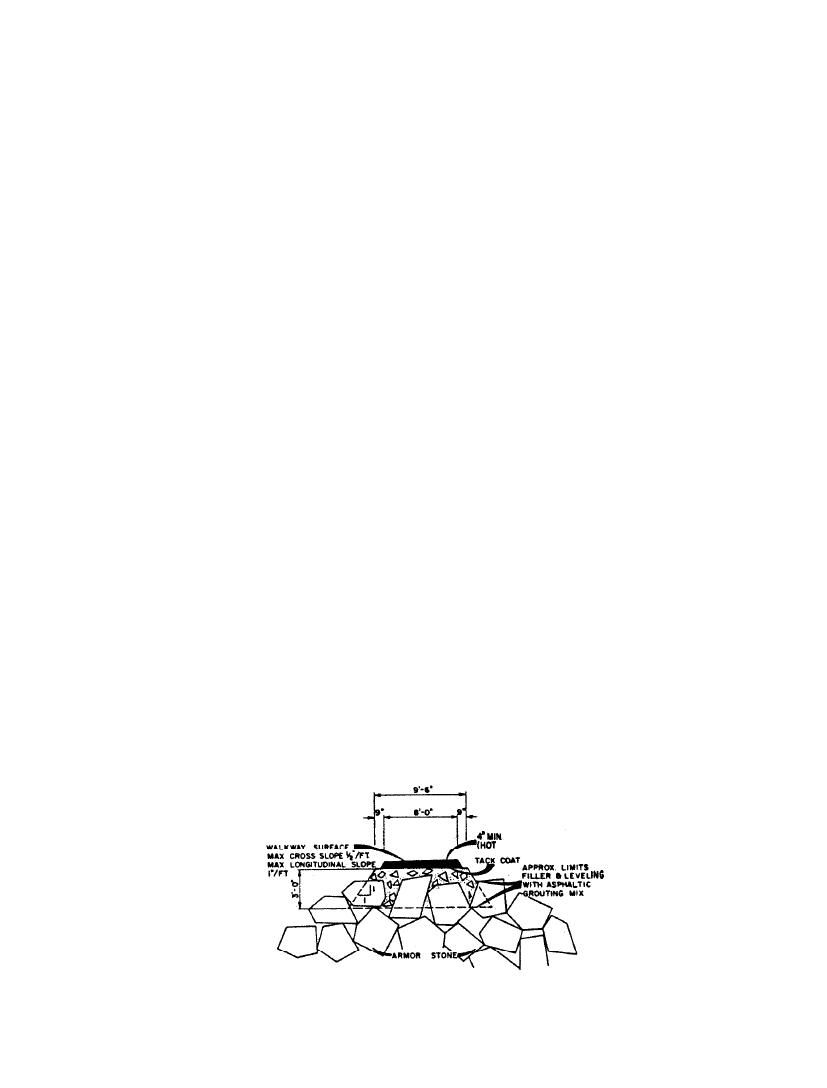

Figure 1 shows a section of the south

jetty with the fishing walkway (US Army Engineer District, Charleston,

1975). The jetty walkway was constructed with asphalt pavement and extended

the 3,600-ft length of the south jetty. The walkway width was established at

8 ft so that trucks carrying materials and equipment could use the jetty

during construction and maintenance operations of the project. The large

voids between the 6-to 8-ton armor stone were filled with smaller leveling

stones and asphaltic concrete grout extending into the structure about 3 ft.

The grout was then capped with about a 4- to 6-in. layer of hot mix asphalt.

While this surface is somewhat flexible, rubble-mound structures tend to shift

under wave attack; therefore, frequent pavement maintenance may be required.

H o w e v e r , after over 4 years, the Murrells Inlet jetty walkway has needed only

minor repair.

Although the walkway at Murrells Inlet does not have safety handrails,

that addition might encourage more public use.

However, of all the publicly-

used coastal structures which have been constructed or modified by the Corps

of Engineers , only about one-fourth have been equipped with handrails. If

only one handrail is installed, generally it should be placed on the beach

side of the jetty structure to avoid impeding access to the deepwater inlet

side which is fished more extensively.

Fishing from the jetty walkway is

difficult due to the side slopes of the structure. As a result, fishermen

climb down nearer the waterline where they may be in danger from wave action

and slippery surfaces.

ASPHALTIC CONCRETE

PLANT MIX)

OF

STONE

CONCRETE

Figure 1.

Fishing Walkway Section

2

Previous Page

Previous Page